Efficiency isn’t just a buzzword; it’s the lifeblood of contemporary industries. Every fraction of a second saved in production or assembly can result in significant gains. Kipp indexing plungers, though often overlooked, play a pivotal role in achieving this efficiency. In this guide, we’ll shed light on these seemingly inconspicuous devices and their critical role in streamlining industrial and manufacturing processes.

Kipp indexing plungers are precision components designed to control and secure the position of moving parts. These unassuming devices consist of a threaded body housing a spring-loaded retractable pin. Engaging the plunger extends the pin, firmly locking the component in place, while disengaging allows for seamless movement.

What Are Kipp Indexing Plungers?

Kipp indexing plungers, also known as retractable indexing plungers, are mechanical devices used in various applications to control and lock the position of moving parts. They consist of a threaded body with a spring-loaded retractable pin. When the plunger is engaged, the pin extends, locking the component in place. Conversely, when disengaged, the pin retracts, allowing for free movement.

These seemingly simple devices are deceptively powerful. They are the unsung heroes in the world of industrial machinery and manufacturing. Kipp indexing plungers excel at providing precision in positioning, ensuring a secure locking mechanism, and boasting impressive durability, even in the harshest of industrial environments.

Benefits of Using Kipp Indexing Plungers

Kipp indexing plungers offer a multitude of benefits, each contributing to enhanced efficiency:

Enhanced Positioning Accuracy: Kipp indexing plungers provide precise control over the positioning of components. This accuracy is crucial in applications where parts need to be aligned with high precision. Whether it’s aligning a crucial component on an assembly line or ensuring the precise placement of a tool, these plungers excel in delivering accuracy.

Secure Locking Mechanism: The spring-loaded pin in Kipp indexing plungers ensures a secure and reliable locking mechanism. It prevents unintended movement, reducing the risk of accidents and damage. This level of security is especially critical in industries where safety and precision are paramount.

Durability: Manufactured from high-quality materials and finishes, Kipp indexing plungers are designed to withstand harsh industrial environments. They are resistant to wear and corrosion, ensuring long-lasting performance and reliability. Whether it’s exposure to extreme temperatures, chemicals, or heavy use, these plungers can handle it.

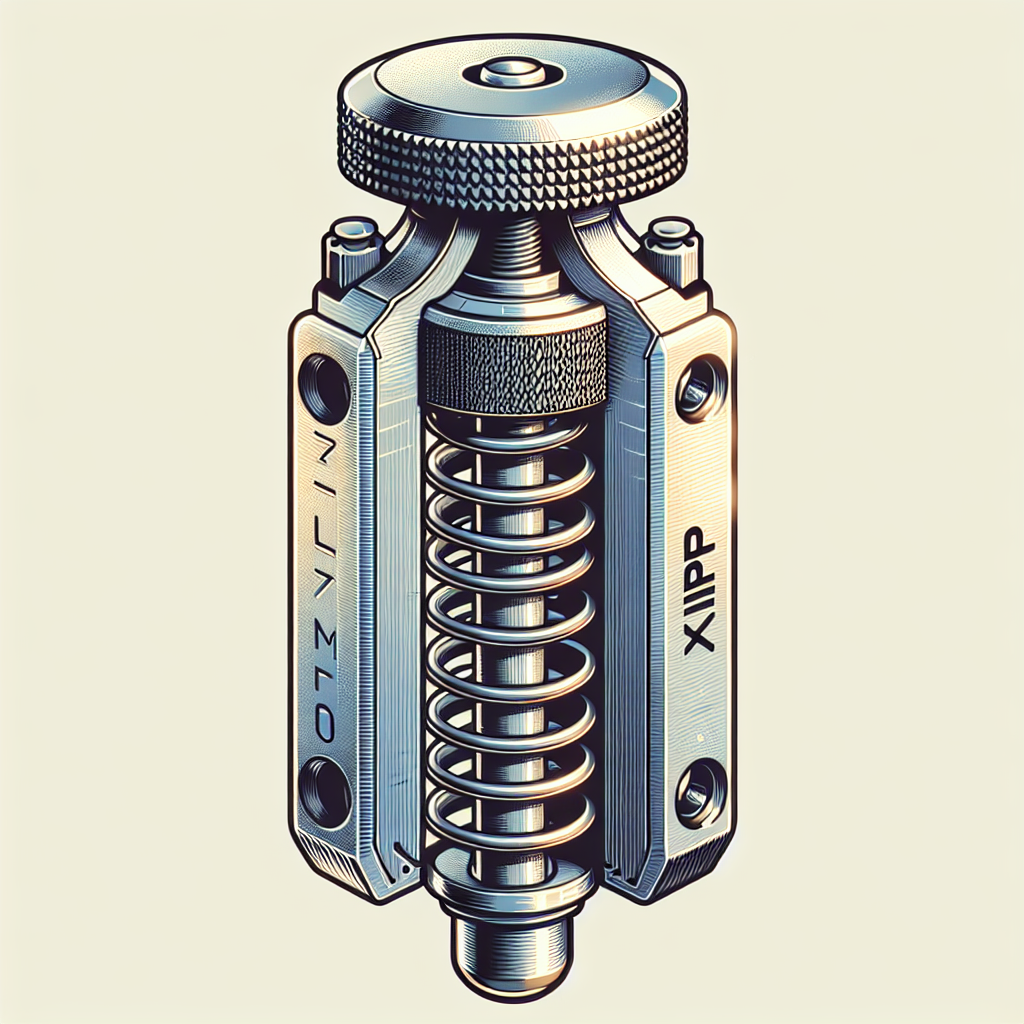

Different Types of Kipp Indexing Plungers

Kipp offers various types of indexing plungers, each tailored to specific applications:

Threaded Indexing Plungers: Threaded indexing plungers are the most common type and are used for applications where the plunger needs to be threaded into place. They offer a secure and adjustable solution for positioning and locking components.

Weldable Indexing Plungers: Weldable indexing plungers are ideal for applications where welding is required to attach the plunger. This type ensures a permanent and robust connection, making it suitable for heavy-duty applications.

Quick-Release Indexing Plungers: Quick-release indexing plungers are designed for applications where rapid engagement and disengagement are necessary. They are a time-saving solution, ideal for situations where speed is crucial.

How to Choose the Right Kipp Indexing Plunger

Selecting the right Kipp indexing plunger is crucial for optimal performance. Here’s a step-by-step guide to help you make the right choice:

Step 1: Determine Your Application Needs

The first step in choosing the right Kipp indexing plunger is to thoroughly assess your application’s specific requirements. Consider factors such as load capacity, temperature conditions, and the environment in which the plunger will operate.

Step 2: Consider Material and Finish

Once you’ve identified your application’s needs, it’s time to consider the material and finish of the plunger. Different materials and finishes offer varying levels of durability and resistance to environmental factors.

Step 3: Size and Mounting Options

Selecting the appropriate size and mounting style is the final step in choosing the right Kipp indexing plunger. The size should match the dimensions of your equipment, and the mounting style should align with your specific requirements. Whether you need a threaded plunger for a secure fit or a weldable one for a permanent attachment, careful consideration of size and mounting options is essential.

Installing and Maintaining Kipp Indexing Plungers

Proper installation and regular maintenance are essential for the longevity and performance of Kipp indexing plungers. Let’s explore the installation process and maintenance tips in detail:

Step 1: Installation Process

Installing a Kipp indexing plunger requires careful attention to detail. Following the manufacturer’s guidelines is essential. Ensure proper alignment and torque specifications to prevent any issues. Proper installation ensures that the plunger functions as intended, providing reliable positioning and locking capabilities.

Step 2: Maintenance Tips

Regular maintenance is crucial to keep Kipp indexing plungers operating smoothly over time. Inspect the plungers regularly for signs of wear and tear. Lubricate moving parts as recommended by the manufacturer to prevent friction and ensure continued reliability. Proper maintenance extends the lifespan of the plungers, reducing the need for replacements and downtime.

Applications of Kipp Indexing Plungers

Kipp indexing plungers find applications across various industries, where they contribute to efficiency and precision. Let’s explore some of these applications in detail:

Industrial Machinery

In the realm of industrial machinery, Kipp indexing plungers play a crucial role in securing components during production processes. They prevent misalignment and ensure that manufacturing operations run smoothly and efficiently. Whether it’s aligning molds or locking machine components in place, these plungers are a valuable asset in industrial settings.

Aerospace and Automotive

In aerospace and automotive assembly, precision is paramount. Kipp indexing plungers aid in aligning critical components with accuracy, ensuring safety and precision throughout the manufacturing process. Whether it’s aligning aircraft parts or securing automotive components, these plungers are trusted for their reliability and precision.

Conclusion

Efficiency remains the holy grail in today’s competitive industries, and Kipp indexing plungers are the unsung heroes that can help you achieve it. By understanding their functionality, advantages, selection criteria, installation process, maintenance practices, and diverse applications, you can elevate efficiency across your operations. Whether you’re involved in industrial machinery, aerospace, or automotive manufacturing, Kipp indexing plungers are your trusted allies for achieving higher productivity and impeccable precision. Don’t underestimate the power of these small yet significant components in maximizing efficiency within your industry.